RVA SERVICES

Demolition and dismantling

From overseeing the total demolition of an entire processing plant, to the careful salvaging of individual items and even the complete dismantling of assets for reinstallation elsewhere, RVA’s objective is always to ensure a robust project delivery, regardless of clients’ experience of such works.

We therefore offer a comprehensive portfolio of demolition and dismantling services, ranging from the full management of these often high hazard projects, through to the more administrative side of the process.

So, whether you are looking for a principal designer, or some engineering expertise to complement your existing scheme of work, talk to us about the value we may be able to add…

Professional engineers and technical advisers

RVA’s discipline-specific engineering expertise can prove invaluable when demolition and dismantling works are underway on a client’s site. From actively assessing and commenting on the method statements put forward by contractors, to maintaining oversight of systems and procedures as the project schedule progresses, our practical, realistic and impartial technical input and ongoing auditing affords clients maximum peace of mind – especially if this is unknown territory.

Environmental permit surrender and lease exit support

RVA can support clients every step of the way with their full or partial surrender of environmental permits, and, if relevant, their progress towards exiting a site lease agreement within a defined timeframe. Our knowledge of this multifaceted process sees us deploy technical know-how which doesn’t just ensure works are carried out compliantly and to the standard required, but that the project is planned meticulously in line with an often non-negotiable schedule.

EU Directive 57/92 and CDM compliance services

The appointment of a Principal Designer is a legal and fundamental requirement for UK decommissioning and demolition projects. This duty holder role is set out under the Construction Design Management (CDM) regulations, which exist to help manage health and safety on these potentially high-hazard assignments.

However, the successful and independent fulfilment of these statutory responsibilities in truth extends far beyond this regulatory framework. In fact, in our opinion, the role of Principal Designer is integral to robust project management and the creation of a ‘safety first’ mindset among every member of the extended demolition and dismantling team.

Regulatory duty holder and legislative compliance support

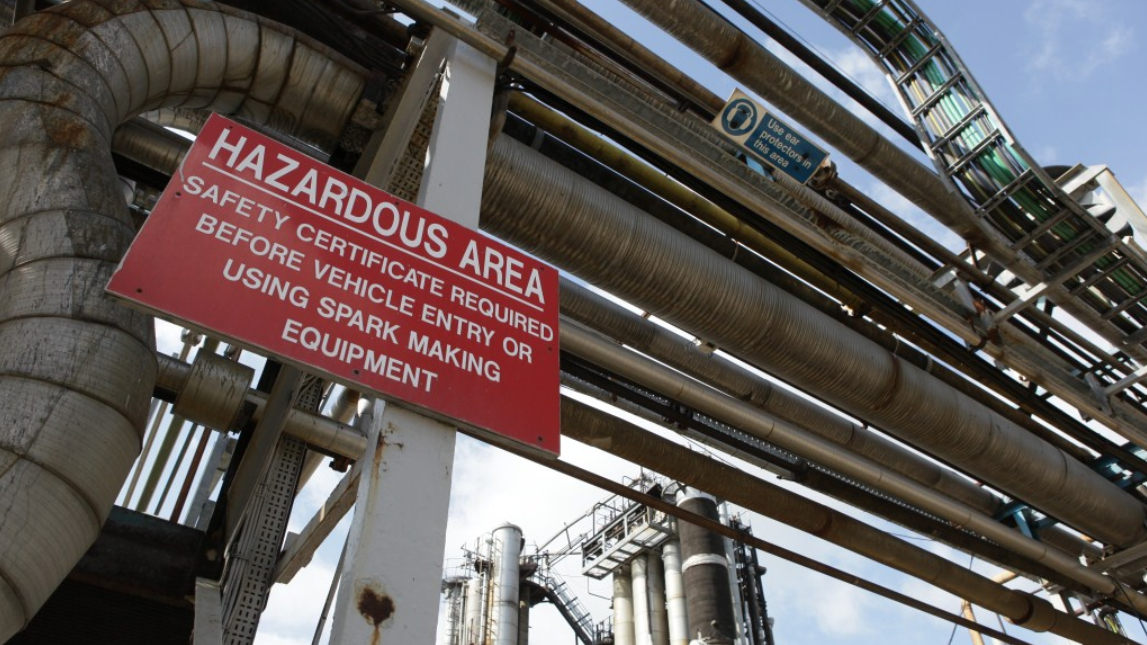

Legislative compliance is an understandable priority for many clients, when a high-hazard demolition or dismantling project is underway. However, regulatory frameworks should in truth represent only the baseline standards for such an assignment.

Comfortable in adopting statutory duty holder responsibilities having assumed this responsibility hundreds of times, all over the world, RVA can oversee all works to ensure compliance with local rules. Experience extends far beyond CDM compliance which is the priority in the UK – with other duty holder protocol including SiGeKo – Planning prescribed by Baustell V in Germany, or the requirements set out in OSHA in North America, to name just a few.

Environmental, Health and Safety management

Safety is absolutely RVA’s number one priority, therefore we always guide and support clients’ teams, to ensure operations are undertaken using best-practice procedures and methodology, which strictly adhere to ever-evolving and increasingly stringent EHS legislation.

Environmental, health and safety plans are compiled in conjunction with other contractual documentation, and strong communication is ensured between client, contractor and RVA to ensure a truly shared responsibility and commitment to upholding agreed standards. The introduction of learning event reporting, open health and safety discussions, and hazard workshops are just some of the tools used.

The result is a cohesive output, with no conflict or misunderstanding when it comes to risk management and the goal to achieve EHS excellence.

Hazardous insulation material surveys management

Before undertaking any demolition or dismantling works, it is important to bring assets to a ‘known state’ so that the ensuing project can be carried out safely and compliantly, without putting personnel or the environment at added risk.

A key part of this approach involves conducting hazardous insulation materials surveys and the removal of contaminants such as asbestos and respirable ceramic fibres. To support clients in this respect, RVA regularly develops the scope of works to procure a specialist contractor, before subsequently managing the appointed team, if required. It is typically our role to oversee the hazardous materials removal process, to keep to programme and progressively monitor the output. This ensures method statements are effective and being followed safely, and the result is an asset that can be dealt with in line with the project plan.

Decommissioning and demolition of Derwent Power Station, Spondon, UK

Following the completion of the above project, I would like to thank the RVA team in helping us to deliver an incident-free outcome, within the budget cost and on programme.

We recognised from the outset that the removal of hazardous materials and demolition of the massive and complex structures was outside our company’s core business activities and hence we sought specialist support.

Specifying work scope

Concise, clear and accurately constructed demolition and dismantling tender documentation is the foundation on which the success of a project relies.

Utilising wide-ranging and relevant experience, RVA formulates a comprehensive suite of specifically tailored documents for each contract. These will typically comprise an EHS plan, works specification, the conditions of contract, bills of quantities and forms of tender. Clients’ specific in-house contractual clauses or conditions can also be readily incorporated into the tender package.

A robust plan at this stage will set the tone for the entire project and help to ensure the right team goes on to be assembled for the work. Ongoing cost control can also be factored in if pricing schedules are requested and financial milestones factored in from the outset.

Contractor procurement

The formation of the right project team will prove critical to its ongoing success, and the competency and experience of those involved is paramount.

Having worked with many different contracting companies over the years, on multiple continents, RVA is trained to recognise strengths and weaknesses. We know what questions to ask and as importantly, what responses to accept.

There are many good demolition and dismantling contractors in the marketplace, however the right team for one project may not be able to effectively execute another. RVA’s knowledge of specialist services and abilities within the competent supply chain – as well as their available capacity – therefore plays a crucial part in assembling the most suitably skilled project team.

Acting in a wholly independent capacity, RVA regularly assists clients with – or fully manages – the contractor assessment and selection process, to bring together the required combination of expertise.

Site management

We operate as part of a project team with, not in opposition to the contractor. RVA will proactively become involved in the development of best practice and best value methodology and, where required, will explore a variety of solutions in order to advance and enhance the project.

RVA’s targeted skill-sets span disciplines including demolition, explosives, chemical, structural and mechanical engineering. As a result, RVA is able to deliver safe, commercially secure, environmentally sound and cost-effective results, even where the circumstances are extremely challenging.

As the needs of every project vary, so too does RVA’s level and type of input. We can provide both resident or visiting management resource and via our directly employed engineering and EHS team, remain flexible to accommodate changing levels of activity over the project lifecycle.

Contract administration

Good housekeeping is key to the successful progress of demolition and dismantling projects, and an audit trail of information, key documentation and dialogue forms a core part of RVA’s contract administration support.

Such administrative services include managing internal and external stakeholder requirements, which sees RVA’s experienced engineers present to or chair discussions with management teams and personnel, community groups, local authorities, enforcing bodies and the emergency services.

We can also assume responsibility for activity such as ongoing cost control, by structuring financial milestones from which to measure ongoing contract visibility and spend certainty.

5 steps towards the perfect ‘plant dismantling for re-erection’ project

At a time when materials reuse and recycling is high on the general environmental agenda, it’s no surprise that the dismantling of plants for re-erection, remains a popular consideration for operators. And that’s before the possible financial advantages are considered.

However, there are naturally numerous criteria to thoroughly evaluate, to ensure that such a dismantling project represents a safe, cost-effective and environmentally sound route for the plant...

Physical, virtual or hybrid decommissioning support

When it comes to our provision of decommissioning services, we can adopt varied deployment methods, including a physical on-site presence, virtual support, or a hybrid approach. Exactly what is feasible will depend on the scope of work involved, and decisions will always be made on the grounds of safety. However, where possible we will actively seek to make best use of technology and remote or geographically diverse resources, to reduce the unnecessary carbon impact of travel, and keep programmes progressing fluidly whatever else may be going on in the world.